Wet Dry Diamond Polishing Pads

MERROCK

Profile.pdf

100MM Merrock Diamond Polishing Pads For Wet / Dry Grinding

Concrete Floor

Quick Detail:

| Name | Merrock Diamond Polishing Pads | Application | Marble, granite, terrazzo, concrete ceramic surface |

| Grit | 50#, 100#, 150#, 200#, 300#, 400#, 500#, 800#, 1000#, 1500#, 2000#,

3000# | Function | Leveling, polishing, grinding |

Description:

Merrock diamond polishing pads is very sharp for grinding and

polishing marble, granite, terrazzo floor

Application:

For leveling, polishing and grinding marble, granite, terrazzo and

concrete floor

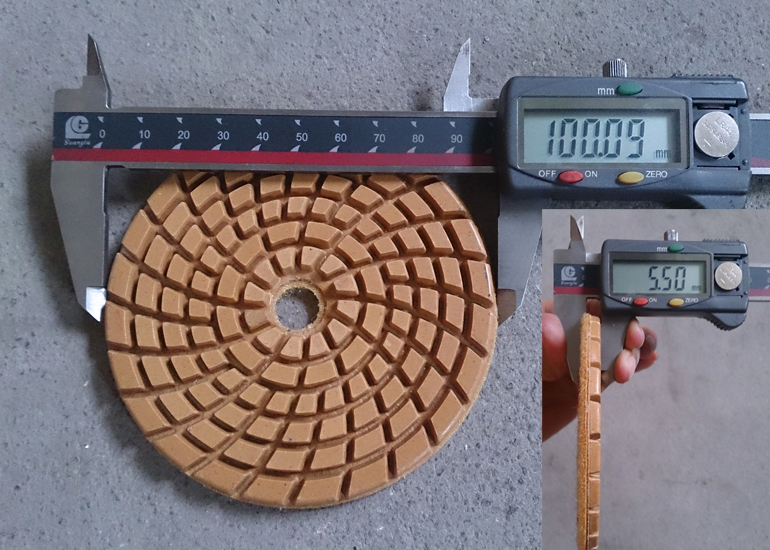

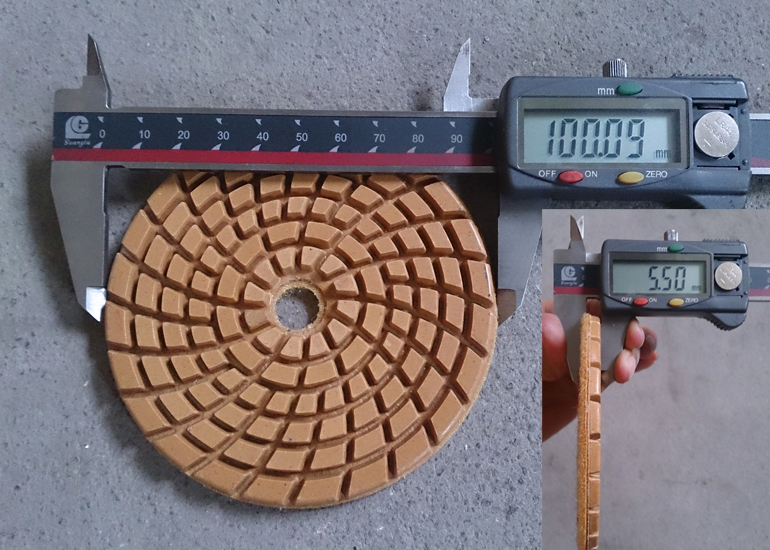

Specification:

- Diameter : 4 "

- Thickness : 5.2mm

- Material : Diamond, resin

- Grit: 50#, 100#, 150#, 200#, 300#, 400#, 500#, 800#, 1000#, 1500#,

2000#, 3000#

Detail picture:

Related products:

1.Diamond resin pads

2. Diamond grinding shoes

3. Metal diamond grinding discs

TIPS:

The Composition of Diamond Tooling

Diamond tooling cuts into concrete and other surfaces using diamond

grains that are bonded onto the functional parts of the tool via a

bonding material or another method. Because the diamond is

considered a super-hard material, diamond tooling has many

advantages compared to tools made with common abrasives such as

corundum and silicon carbide.

High grinding efficiency, low grinding force: Less heat is

generated by the hole in the grinding process, which decreases or

avoids burns and cracks on the surface, the equipment’s wear and

energy consumption.

Long lifespan, long dressing period: This can greatly increase the

work efficiency, improve the work environment and decrease labor

intensity.

Low comprehensive cost: Diamond tooling is designed to yield the

best possible productivity and cost per square foot for the

contractor, so that they have the best chance at being profitable

on every job.

High wear resistance: Diamond tooling’ s change in dimension is

small, performing with good grinding quality and precision.

Diamond tooling are composed of several elements which are

diamonds, grits and bond.

Diamonds

The word “diamond” in “diamond tooling” is not a metaphor. Actual

diamonds are built into the surface of the tooling as an abrasive.

It is the hardest natural substance on Earth. This means that

diamonds can cut every other substance, including itself.

Grits

The grit of a diamond tool refers to the size of the individual

diamonds used in that tool. Lower numbers indicate larger diamonds,

while higher numbers indicate smaller diamonds and a finer grit.

Bond

In order for a grinder to use diamonds to cut, small chips of

diamonds are suspended in a bond made from metal, resin, ceramic,

hybrid or polycrystalline diamond (PCD).