Application:

For terrazzo floor leveling, marble granite floor polishing and

grinding, concrete polishing and grinding, also apply to remove the

old coat of epoxy etc...

| Model | MRK-V6-220B | MRK-V6-380B |

| Phase | 1 | 3 |

| Voltage | 220V | 380V |

| Power | 5.5HP/4KW | 5.5HP/4KW |

| Inverter | 5.5HP/4KW | 5.5HP/4KW |

| Speed | 0-1500rpm |

| Work width | 310*550mm |

| Heads | 6 pieces |

| Grinding plate | 2 pieces |

| Water tank | 30L |

| NW(KG) | 170+20 |

| GW(KG) | 230 |

| Packing size(CM) | 76x66x134cm |

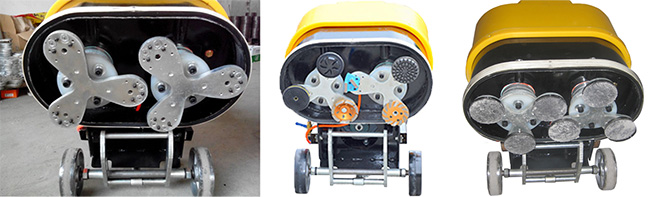

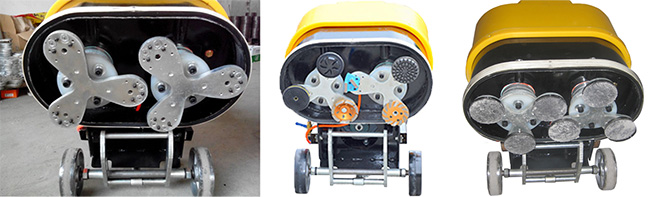

Detail picture:

Two Heads Single Phase 30L Terrazzo Polishing Machine with vaccum

interface

Two Heads Single Phase 30L Terrazzo Polishing Machine with 1 piece

dust skirt, 2 pieces lift pole, 1 piece add weight

Available abrasive:

Diamond resin pads

1. Wet polishing pad for wet grinding the marble, granite, terrazzo

and concrete floor

2. Dry polishing pad for dry polishing the marble, granite, terrazzo and concrete floor

3. Renovation pad for wet grinding and polishing the marble,

granite, terrazzo and concrete floor

Available blades:

Diamond grinding shoes

Packing:

V6-V12

concrete grinder.pdf

Tag: marble

floor polishing machine, concrete

floor grinding machine

What is Diamond Grinding?

Polished concrete is a craft that tends to be misunderstood. Often

when people hear about polished concrete, they assume it is

achieved through the application of a topical product or that it

defines a cleaning process that makes the floor appear shiny.

However, neither of these accurately describe the process of

mechanically refined polished concrete. Polished concrete is a

detailed, labor and skill-intensive process that requires highly

specialized tooling and training to produce. One of the numerous

tools required in this process is a grinder with diamond tooling.

Nowadays, most of the concrete grinding is performed by diamonds.

This process is called as “diamond grinding”. Grinding concrete

with diamond tooling is a mechanical process that renews worn or

irregular concrete surfaces. It uses specialized tooling to produce

a smoother surface and reduce concrete failures such as joint

faults, warped slabs, and traffic wear. Due to the power needed to

grind concrete, the diamond tools can quickly overheat during a wet

grind process. Overheating is prevented by cooling the machine with

water. However, this means a slurry is produced from the grinding

and water excreted but the slurry is removed and disposed of. Dry

grinding is also done with an air-cooled system. Both options can

achieve the same desired result.